Description

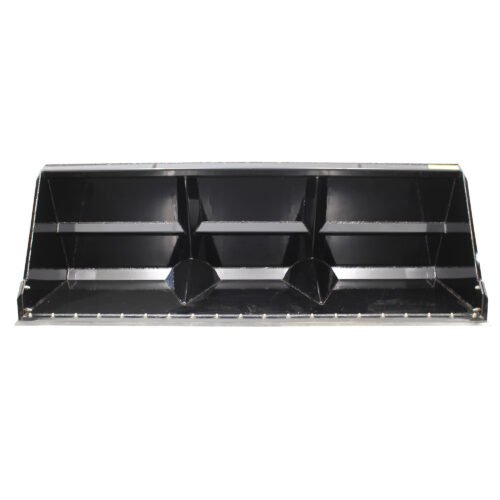

- Easily pick up rocks and leave the dirt in the fields with your Messer Repair & Fabricating Rock Bucket Grapple’s. We use a one-piece tooth design to make this bucket even stronger. What that means is we cut both the tooth and the back out of one-piece steel, instead of cutting and welding the back edge. It does cost more to do it that way, however it also means it will be more durable.

- Our teeth are made from 3/8” grade 50 steel (which is 30% stronger), with a 3” spacing between teeth, and are connected to each other with a ¾” by 2” solid flat bar. We use an AR400 steel* cutting edge on the front, and include a flat bar on the rear, to allow this versatile attachment to double as a land leveler. This high visibility design also features a rock dam and tooth notch to hold back rocks while digging.

- *AR400(Abrasion Resistant) steel has a higher carbon content and receives heat treatment which makes the wear resistance and hardness 4-5X greater than A36 steel.

- We include bolt-on sides on our rock bucket grapples, which can be removed if desired to use for brush, logs, manure, or anything else longer than this bucket.

- Our dual grapple hooks are made of ½” grade 50 steel (which is 30% stronger) and operate independently. The benefit to that, is that you will be able to efficiently clamp uneven loads, and also prevents flexing and cracking by having two hooks verses one.

- They come standard with base end cylinder guards; however, rod end guards are available as an optional purchase to achieve the ultimate protection for extreme applications. All pivot points are greaseable. We “T” together our hydraulic hoses in the center under the step, run them through the top tube, and clamp them near the loader bucket pivot so there is no change in hose length, to help avoid pinch points. We also wrap the hoses in an abrasion resistant sleeve to help protect the hydraulic hoses from damage, as well as flat face couplers.

- The hoses are also routed through and to the left, to be closer to the skid loader connector (can be routed out the right side upon request), and to keep hoses out of the way from getting pinched. We test all of our hydraulic items at full pressure with hydraulic oil to ensure they work correctly. We send them out full with oil, so they are ready to go to work as soon as you get them, without having to top off the hydraulic oil reservoir in your machine.

- We do all the sand blasting and powder coating on site at MRF, so we can guarantee the quality. This is one of the reasons we provide a 2-year warranty and 30-day satisfaction guarantee on all our products.

Reviews

There are no reviews yet.