When selecting the optimal grapple for heavy-duty land clearing, log handling, and debris removal, understanding the distinct advantages of Messer Brush Grapples and John Deere Root Grapples is crucial. Each grapple type is engineered for specific tasks, and pairing them with the appropriate John Deere front-end loader is essential to maximize performance and efficiency.

Comparison of Messer Brush Grapples vs. John Deere Frontier Root Grapples

The Messer Brush Grapples and John Deere Frontier Root Grapples differ significantly in design, structure, and functionality. This comparison delves into their key features, compatibility, and ideal use cases to help you decide based on your operational needs.

Key Differences: Full Tooth Design vs. Skeleton Design

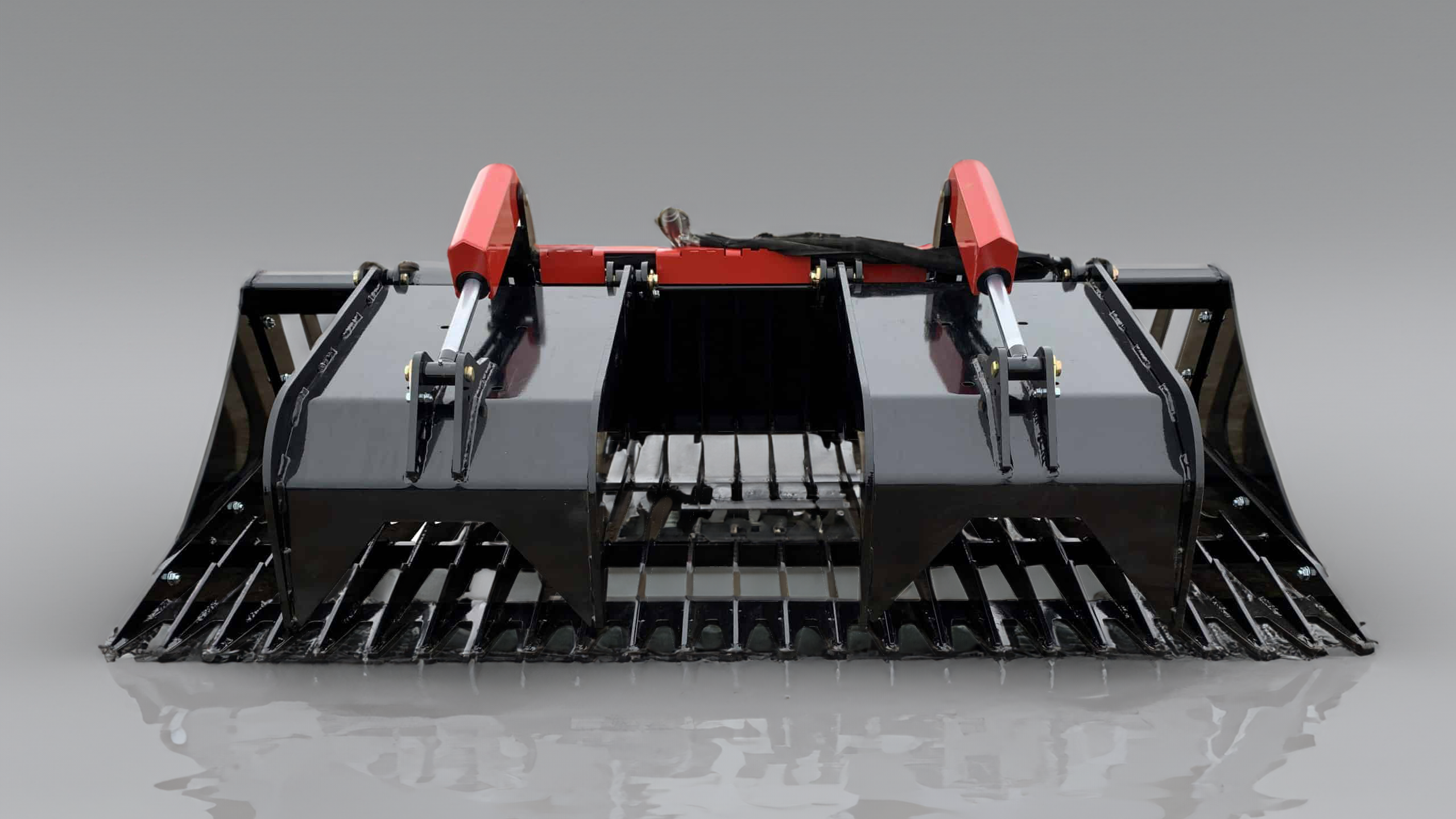

Messer Brush Grapples

- Complete Tooth Design

- Description: Messer Brush Grapples feature closely spaced tines with a 6-inch spacing.

- Advantages: Ideal for grabbing acceptable debris, small branches, roots, and larger logs or stumps. The dense tine configuration allows for precise material handling.

- Independent Grapple Hooks

- Description: Each grapple is equipped with independent hooks.

- Advantages: Provides better control over uneven loads and debris, enhancing maneuverability and handling efficiency.

John Deere Frontier Root Grapples

- Skeleton Design

- Description: Frontier Root Grapples, such as the AV20G and AV20E models, feature wider tine spacing with fewer tines.

- Advantages: This design is more suitable for handling larger, bulkier debris like logs and branches while allowing smaller debris to fall through. It is particularly effective for storm cleanup and forestry work.

- Full-Width Clamping

- Description: Equipped with a full-width clamping system.

- Advantages: Securely holds large materials during transport, ensuring stability and safety when moving heavy or oversized debris.

Detailed Brush Cutter Feature Comparison

| Feature | Messer Brush BG78M | Messer Brush BG85M | John Deere AV20E | John Deere AV20G |

|---|---|---|---|---|

| Brand | Messer | Messer | John Deere Frontier | John Deere Frontier |

| Working Width | Skid steers, multiple brands | 85″ (215.9 cm) | 62″ (157.5 cm) | 77″ (195.6 cm) |

| Loader Compatibility | Skid steers, multiple brands | Skid steers, various brands | 500 and 600 Series Loaders | 500 and 600 Series Loaders |

| Teeth Design | Full Tooth: 6″ tine spacing | Full Tooth: 6″ tine spacing | Skeleton Design: fewer, wider-spaced tines | Skeleton Design: fewer, wider-spaced tines |

| Weight | 790 lbs (358.3 kg) | 815 lbs (369.7 kg) | 790 lbs (358.3 kg) | 970 lbs (439.9 kg) |

| Hydraulic System | 2 Cylinders (3500 psi) | 2 Cylinders (3500 psi) | Dual Independent Cylinders (2″ x 10″) | Dual Independent Cylinders (2″ x 10″) |

| Grapple Opening | 42″ (106.7 cm) | 42″ (106.7 cm) | 50″ (127 cm) | 50″ (127 cm) |

| Primary Use | Forestry, log handling | Heavy-duty forestry, log handling | Medium-to-large debris removal | Heavy-duty debris and material handling |

| Build Features | Greasable pivot points, cylinder guards | Greasable pivot points, cylinder guards | Replaceable wear tips, parking stands | Replaceable wear tips, parking stands |

| Hydraulic Features | Higher PSI (3500) | Higher PSI (3500) | Dual independent for medium clamping force | Dual independent cylinders for heavy-duty clamping |

Key Design Differences

Teeth Design and Spacing

- Messer Brush Grapples:

- Design: Close 6-inch tine spacing.

- Benefit: Offers excellent control over both fine and large debris, making it ideal for precise land clearing and versatile material handling.

- John Deere Frontier Root Grapples:

- Design: Wider tine spacing with fewer tines.

- Benefit: Better suited for bulkier debris, such as large logs and branches, while allowing smaller debris to pass through. It is ideal for tasks like storm cleanup and extensive forestry work.

Material Handling

- Messer Brush Grapples:

- Construction: Made with high-strength Grade 50 steel.

- Capability: They excel at handling fine and large debris, logs, and stumps simultaneously, making them perfect for comprehensive land-clearing tasks.

- John Deere Frontier Root Grapples:

- Construction: Engineered for bulk material handling.

- Capability: Efficiently removes large branches and logs, with the design allowing smaller materials to fall through, streamlining the debris removal process.

Weight and Build

- Messer Brush Grapples:

- Weight: Heavier models weigh up to 815 lbs (369.7 kg).

- Advantage: Provides enhanced durability and stability, making them ideal for heavy-duty operations requiring robust performance.

- John Deere Frontier Root Grapples:

- Weight: AV20G weighs 970 lbs (439.9 kg), while AV20E weighs 790 lbs (358.3 kg).

- Advantage: The heavier AV20G is suitable for heavy-duty loaders, whereas the lighter AV20E offers compatibility with medium-duty loaders, providing flexibility based on loader capacity.

Hydraulic System

- Messer Brush Grapples:

- Configuration: Equipped with 2 cylinders operating at 3500 psi.

- Benefit: It delivers stronger clamping power, which is essential for handling heavy-duty applications and ensuring a secure grip on large debris.

- John Deere Frontier Root Grapples:

- Configuration: Dual independent cylinders with a hydraulic pressure of 3000 psi.

- Benefit: It provides better control when handling large debris. Although it has slightly lower hydraulic pressure than Messer, it remains effective for medium—to heavy-duty tasks.

Compatibility Table: John Deere Loader Models & Messer Brush Grapple Sizes

Matching your John Deere loader model with the appropriate Messer Brush Grapple size is essential to ensure optimal performance. Below is a compatibility table outlining the suitable combinations.

Selecting the Right Loader for Your Messer Brush Grapple

Choosing the appropriate John Deere loader for your Messer Brush Grapple involves matching the loader’s lift capacity and hydraulic flow rate with the grapple’s specifications. Here are some key considerations:

Messer Brush Grapple Sizes

BG72M

- Working Width: 72″

- Primary Use: Heavy-duty land clearing, fine debris, logs, and stumps.

- Compatible Loaders: Mid-size to heavy-duty loaders (e.g., 300E Loader, 440R Loader, 500M Loader).

BG78M

- Working Width: 78″

- Primary Use: Forestry, log handling, and medium-to-large debris removal.

- Compatible Loaders: Mid-size to large loaders (e.g., 300E Loader, 440R Loader, 500M Loader).

BG85M

- Working Width: 85″

- Primary Use: Heavy-duty forestry, large debris, and material handling.

- Compatible Loaders: Large to heavy-duty loaders (e.g., 500M Loader, 540M Loader, H480 Loader).

John Deere Loader Models

- Mid-Size Front-End Loaders

- Models: 300E, 300R, 320R, 400E

- Compatible Grapples: BG72M, BG78M, BG85M

- Large Front-End Loaders

- Models: 440R, 500E, 500M, 520M

- Compatible Grapples: BG72M, BG78M, BG85M

- Heavy-Duty Front-End Loaders

- Models: 540M, 540R, 600R, 620R, 640R, 660R, 680R, 700M, H160, H310, H360, H380, H480

- Compatible Grapples: BG72M, BG78M, BG85M

Key Considerations for Selecting the Right Loader and Grapple Combination

- Loader Capacity

- Importance: Ensuring the loader can handle the grapple’s weight prevents equipment strain and maintains operational efficiency.

- Tip: Refer to the loader’s specifications to verify that lift capacity exceeds the grapple’s weight.

- Hydraulic Compatibility

- Importance: For optimal performance, Messer Brush Grapples require specific hydraulic flow rates and pressures.

- Tip: Verify that the loader’s hydraulic system meets the grapple’s requirements, typically 3500 psi for Messer Brush models.

- Working Width

- Importance: The grapple size should complement the loader’s size and the scope of your projects.

- Tip: Larger grapples (BG85M) are suitable for extensive land clearing and handling more considerable debris, while smaller grapples (BG72M) are ideal for more precise tasks.

- Mounting Compatibility

- Importance: Proper alignment of mounting points is crucial for safe and effective operation.

- Tip: Ensure the grapple’s mounting system aligns with your loader’s attachment points.

- Application Needs

- Importance: Different grapples are designed for specific tasks.

- Tip: To ensure optimal performance, select a grapple that is suitable for your primary use case, such as land clearing, log handling, or debris removal.

Why Choose Messer Brush Grapples?

Messer Brush Grapples stand out in the market due to their robust construction, efficient material handling capabilities, and versatile compatibility with a wide range of loaders. Here’s why they are an excellent choice for your heavy-duty material handling needs:

Built for Tough Jobs

- Description: Designed to excel in demanding environments such as construction sites, land clearing operations, and forestry projects.

- Benefit: Their robust construction ensures they can easily handle challenging tasks.

Durable Construction

- Description: Crafted from high-strength Grade 50 steel.

- Benefit: Offers exceptional longevity and resilience, allowing grapples to withstand harsh conditions and heavy use without compromising performance.

Efficient Material Handling

- Description: Features precise 6-inch spacing between the teeth.

- Benefit: Provides excellent control over small and large debris, enhancing operational efficiency and accuracy during material handling.

Versatile Compatibility

- Description: Seamlessly integrates with a wide range of John Deere loaders, from mid-size to heavy-duty models.

- Benefit: It ensures that you can integrate it into your existing equipment setup without hassle, providing flexibility across different operations.

Enhanced Control

- Description: Equipped with independent grapple hooks.

- Benefit: Offers superior maneuverability and better handling of uneven or bulky loads, improving overall productivity and control during operations.

Why Choose John Deere Frontier Root Grapples?

While the focus is often on Messer Brush Grapples, John Deere Frontier Root Grapples also offer valuable advantages, especially for specific applications:

Optimized for Bulk Material Handling

- Description: The skeleton design with wider tine spacing is perfect for handling large, bulky debris.

- Benefit: Efficiently removes large branches and logs while allowing smaller debris to pass, streamlining cleanup processes.

Full-Width Clamping System

- Description: Ensures secure holding of large materials during transport.

- Benefit: Enhances safety and stability when moving heavy or oversized debris, reducing the risk of accidental drops or load shifts.

Versatility in Forestry and Storm Cleanup

- Description: Designed to manage a variety of debris sizes effectively.

- Benefit: They are ideal for handling large and medium-sized debris, making them suitable for diverse operational needs.

Practical Applications and Use Cases

Messer Brush Grapples

Land Clearing

- Scenario: Efficiently removing brush, small trees, and stumps from large land areas.

- Benefit: The full tooth design ensures precise removal without leaving behind unwanted debris.

Log Handling

- Scenario: Moving and stacking logs for processing or transport.

- Benefit: Independent grapple hooks provide better control over varying sizes and shapes of logs.

Debris Removal

- Scenario: Clearing construction sites of mixed debris.

- Benefit: The versatile tooth spacing handles both fine and large debris simultaneously, improving cleanup efficiency.

John Deere Frontier Root Grapples

Storm Cleanup

- Scenario: Removing fallen trees and large branches after a storm.

- Benefit: The skeleton design effectively handles large debris while allowing smaller materials to pass through, speeding up the cleanup process.

Forestry Operations

- Scenario: Managing large volumes of forestry debris in logging operations.

- Benefit: The full-width clamping system ensures secure handling of substantial logs and branches, enhancing operational safety.

Bulk Material Handling

- Scenario: Transporting large materials such as pallets or construction timber.

- Benefit: The design is optimized for securely holding and moving oversized materials without spillage.

Loader Compatibility and Recommendations

To maximize the performance of your Messer Brush Grapples, pairing them with the correct John Deere loader is essential. Here’s a guide to ensure compatibility:

Messer Brush Grapple Sizes

- BG72M

- Working Width: 72″ (182.8 cm)

- Primary Use: Heavy-duty land clearing, fine debris, logs, and stumps.

- Compatible Loaders: Mid-size to heavy-duty loaders (e.g., 300E, 440R, 500M).

- BG78M

- Working Width: 78″ (198.1 cm)

- Primary Use: Forestry, log handling, and medium-to-large debris removal.

- Compatible Loaders: Mid-size to large loaders (e.g., 300E, 440R, 500M).

- BG85M

- Working Width: 85″ (215.9 cm)

- Primary Use: Heavy-duty forestry, large debris, and material handling.

- Compatible Loaders: Large to heavy-duty loaders (e.g., 500M, 540M, H480).

John Deere Loader Models

- Mid-Size Front-End Loaders

- Models: 300E, 300R, 320R, 400E

- Compatible Grapples: BG72M, BG78M, BG85M

- Large Front-End Loaders

- Models: 440R, 500E, 500M, 520M

- Compatible Grapples: BG72M, BG78M, BG85M

- Heavy-Duty Front-End Loaders

- Models: 540M, 540R, 600R, 620R, 640R, 660R, 680R, 700M, H160, H310, H360, H380, H480

- Compatible Grapples: BG72M, BG78M, BG85M

Enhancing Your Operations with Messer Brush Grapples

By choosing Messer Brush Grapples, you invest in a tool that combines durability, efficiency, and versatility, making it the ideal solution for your heavy-duty material handling needs. Here’s a summary of their key benefits:

Durable Construction

- High-Strength Grade 50 Steel

- Benefit: Ensures longevity and resilience in demanding environments.

Efficient Material Handling

- 6-Inch Tooth Spacing

- Benefit: Provides precise control over various debris sizes, enhancing operational efficiency.

Versatile Compatibility

- Wide Range of Loaders

- Benefit: Seamlessly integrates with various John Deere loaders, offering flexibility across different operational scales.

Enhanced Control

- Independent Grapple Hooks

- Benefit: Improve maneuverability and handling of uneven or bulky loads, boosting productivity.

Conclusion

Selecting the correct grapple for your John Deere loader is pivotal for maximizing efficiency and ensuring the longevity of your equipment. Messer Brush Grapples offer superior durability, efficient material handling, and versatile compatibility, making them an excellent choice for heavy-duty tasks such as land clearing, log handling, and debris removal. On the other hand, John Deere Frontier Root Grapples provides a robust solution for bulk material handling and storm cleanup with their skeleton design and full-width clamping system.

Recommendation

Assess your specific operational needs, loader compatibility, and the types of materials you handle most frequently. Messer Brush Grapples are the optimal choice for handling fine and large debris on a heavy-duty basis. John Deere Frontier Root Grapples offers a lighter, more versatile solution for handling bulk material and storm cleanup. Always consult your equipment dealer or a Messer representative to verify compatibility and obtain personalized recommendations tailored to your unique operational requirements.

Additional Resources

- Messer Brush Grapples Product Page: Messer Website

Leave a Reply

You must be logged in to post a comment.