In the world of heavy machinery, versatility and efficiency are key. The JRB 500 custom connection offers a comprehensive lineup of attachments for wheel loaders, transforming them into multi-purpose tools capable of handling a wide array of tasks. From bale handling to high-dump loading, the JRB 500 enhances productivity on construction sites, farms, recycling centers, and more.

Table of Contents

- Understanding the JRB 500 Series

- Key Attachments and Their Applications

- Compatibility with Wheel Loader Brands and Models

- Maximizing Efficiency with JRB Attachments

- Best Practices for Selecting and Using JRB Attachments

- Frequently Asked Questions

- Conclusion

Understanding the JRB 500 Series

What Is the JRB 500 Series?

The JRB 500 Series is a collection of high-quality attachments designed for wheel loaders. These attachments expand the capabilities of your equipment, allowing you to perform multiple tasks with a single machine.

Why Choose JRB Attachments?

- Versatility: Transform your wheel loader to handle various tasks like digging, lifting, loading, and material handling.

- Efficiency: Quick attachment changes reduce downtime and increase productivity.

- Durability: Built with robust materials to withstand harsh working conditions.

- Safety: Engineered to meet safety standards, reducing the risk of accidents.

Essential JRB 500 Attachments and Their Applications

JRB 500 Heavy-Duty Bale Spears by Messer Attachments

Purpose: Designed for efficient bale handling in agricultural settings.

Features:

- Heavy-Duty Spears: Penetrate and lift bales securely.

- What Is the JRB 500 Series?

- The JRB 500 Series is a collection of high-quality attachments designed for wheel loaders. These attachments expand the capabilities of your equipment, allowing you to perform multiple tasks with a single machine.

- Durable Construction: Built to handle heavy loads repeatedly.

Applications:

- Transporting hay, straw, and other baled materials.

- Loading and unloading bales from trailers.

JRB Multi-Purpose Bucket

Purpose: A versatile tool for general contractors and utility work. Palladin

Features:

- Multi-Functionality: Digging, loading, lifting, pulling, grabbing, and dozing.

- Robust Design: Handles a variety of materials, from soil to debris.

- Hydraulic Controls: Enhanced precision in operations.

Applications:

- Site preparation and cleanup.

- Material handling in construction and landscaping.

- Demolition tasks require grabbing and pulling.

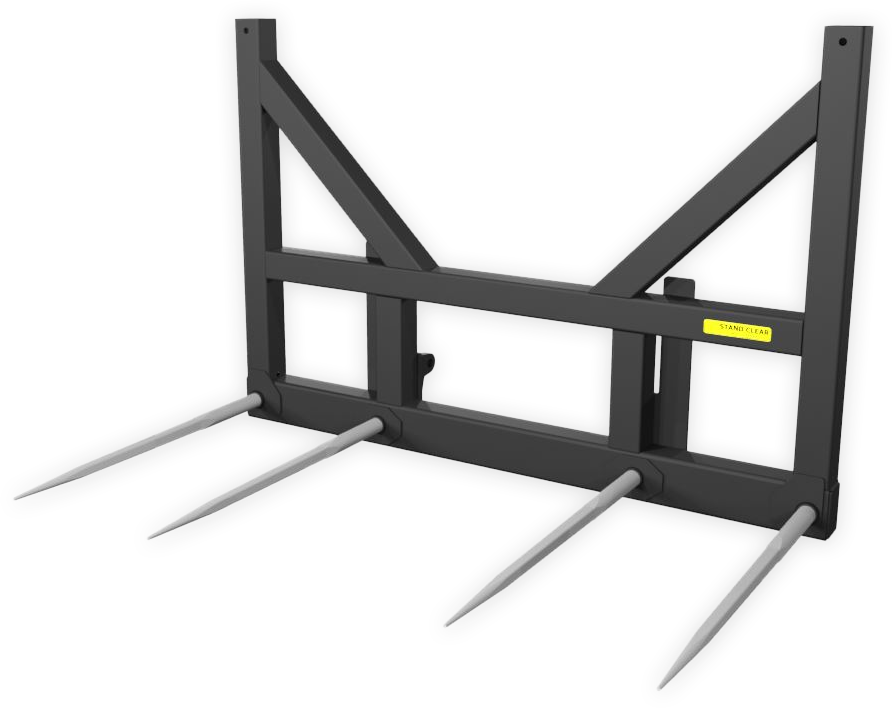

JRB Construction Utility Forks

Purpose: Ideal for transporting large construction materials.

Features:

- Adjustable Tines: These are available in manual or hydraulic adjustments from the cab.

- Heavy Load Capacity: Designed to carry pipes, pallets, and large bulk items.

- Visibility: Open frame design for better operator visibility.

Applications:

- Moving construction materials on-site.

- Loading and unloading pallets and pipes.

- Utility work requiring precise material placement.

JRB High-Dump Bucket

Purpose: Facilitates high-level dumping for increased efficiency.

Features:

- Extended Reach: Allows dumping at higher elevations.

- Large Capacity: Handles substantial volumes of material.

- Hydraulic Operation: Smooth and controlled dumping action.

Applications:

- Operations in recycling centers and landfills.

- Loading materials into high-sided trucks or hoppers.

- Feed truck loading in agricultural settings.

JRB General Purpose Curved Bucket

Purpose: A reliable tool for general loading tasks.

Features:

- Curved Design: Enhances loading efficiency and material retention.

- Versatile Use: Suitable for various materials, including gravel, sand, and soil.

- Durable Edges: Reinforced cutting edges for extended life.

Applications:

- General material handling in construction.

- Landscaping and site development.

- Aggregate loading and transport.

JRB Bug Coupler

Purpose: Revolutionizes attachment changes with its universal compatibility.

Features:

- Fully Automatic: Quick coupler system requiring no manual intervention.

- Universal Fit: Compatible with buckets and attachments from various manufacturers.

- Safety Mechanisms: Built-in features to prevent accidental releases.

Applications:

- Rapid switching between attachments.

- Multi-brand equipment fleets need a universal coupling solution.

- Enhancing productivity with minimal downtime.

Compatibility with Wheel Loader Brands and Models

The JRB 500 Series attachments are compatible with a range of wheel loaders from leading manufacturers. Below is a summary of compatible models.

Caterpillar JRB 500

| Series | Models |

|---|---|

| K-Series | 924K, 930K, 938K, 950K, 962K |

| M-Series | 924M, 930M, 938M, 950M, 962M |

| H-Series | 924H, 930H, 938H |

Komatsu JRB 500

| Series | Models |

|---|---|

| 8 Series | WA200-8, WA250-8, WA270-8, WA320-8 |

| 7 Series | WA200-7, WA250-7, WA270-7, WA320-7 |

John Deere JRB 500

| Series | Models |

|---|---|

| K-Series | 544K, 624K, 644K, 724K, 744K, 824K |

| J-Series | 544J, 624J, 644J, 724J, 744J |

Volvo Construction Equipment JRB 500

| Series | Models |

|---|---|

| H-Series | L60H, L70H, L90H, L110H, L120H |

| G-Series | L60G, L70G, L90G, L110G, L120G |

Case Construction Equipment JRB 500

| Series | Models |

|---|---|

| F-Series | 621F, 721F, 821F, 921F, 1021F |

| E-Series | 621E, 721E, 821E, 921E |

Hyundai Construction Equipment JRB 500

| Series | Models |

|---|---|

| 9 Series | HL730-9, HL740-9, HL757-9, HL760-9 |

| 7A Series | HL740-7A, HL757-7A, HL760-7A |

JCB JRB 500

| Models |

|---|

| 411, 417, 427, 437, 457 |

Note: Compatibility may vary based on the specific attachment and model year. Always consult with manufacturers or authorized dealers to confirm compatibility.

Maximizing Efficiency with JRB Attachments

Applications Across Industries

- Construction: Enhanced material handling, site preparation, and demolition tasks.

- Agriculture: Efficient bale handling, feed loading, and transport.

- Landscaping: Versatile tool for moving soil, mulch, and other materials.

- Waste Management: High-dump capabilities for recycling centers and landfills.

- Utility Work: Precise placement and transport of materials like pipes and pallets.

Benefits of Using JRB Attachments

- Increased Productivity: Rapid attachment changes and specialized tools reduce task completion times.

- Cost Savings: One machine can perform multiple functions, reducing the need for additional equipment.

- Operational Flexibility: Adapt to various tasks and job site requirements with ease.

- Enhanced Safety: Purpose-built attachments reduce the risk of accidents compared to makeshift solutions.

Best Practices for Selecting and Using JRB 500 Type Connection

Consult with Dealers and Manufacturers

- Verify Compatibility: Ensure the attachment fits your specific wheel loader model.

- Stay Updated: Keep abreast of new attachments or updates that may benefit your operations.

- Expert Advice: Leverage dealer expertise to select the most suitable attachments.

Safety Considerations

- Operator Training: Ensure operators are trained in the use of each attachment.

- Regular Maintenance: Perform routine checks and maintenance to keep attachments in optimal condition.

- Follow Guidelines: Adhere to manufacturer instructions for safe and effective use.

Maintenance Tips

- Inspection: Regularly inspect attachments for signs of wear or damage.

- Lubrication: Keep moving parts well-lubricated to prevent premature wear.

- Storage: Store attachments in a dry, secure area when not in use.

Frequently Asked Questions

Can I use JRB attachments on different brands of wheel loaders?

Many JRB attachments are designed for universal compatibility, primarily when used with the JRB Bug Coupler. However, always verify with the manufacturer or dealer.

How do I know which attachment is proper for my needs?

Assess the tasks you need to perform and consult with a JRB dealer who can recommend the appropriate attachments based on your wheel loader model and job requirements.

Are there financing options available to purchase JRB attachments?

Many dealers offer financing options. Contact your local dealer to discuss available plans.

How often should I service my JRB attachments?

Follow the manufacturer’s recommended maintenance schedule, which typically includes regular inspections and servicing after several operational hours.

Conclusion

The JRB 500 Series attachments significantly expand the capabilities of wheel loaders, turning them into versatile machines ready to tackle many tasks. Choosing the right attachments and following best practices can enhance productivity, reduce costs, and maintain high safety standards on your job site. Always consult with manufacturers or authorized dealers to ensure compatibility and get the most out of your equipment.

Remember: The proper attachment improves efficiency and ensures the safety and longevity of your equipment. Invest wisely and operate safely.

Leave a Reply

You must be logged in to post a comment.